VIBRATING SCREENS

Vibrating screens are inclined at 15°, two bearing type, and are positioned on spiral springs properly selected to preserve the vibration. Their operation is based on the vibration produced by the embedded vibrating mechanism. They have a robust construction and their performance rate reaches 95%. The vibrating screens are constructed in different dimensions and screening levels, depending on each application’s requirements.

Vibrating Screens/Washers: Designed for washing the screening material. The hydraulic system consists of piping, becks and high pressure pump. The delivery chute is specially designed to collect the undersize material with the water to send it to the dewatering screws.

Vibrating Screens Closed-type: Used in applications where dust suppression is required. The screens are specially designed to accomodate covers and chutes. The covers are connected to the main body of the screen with special rubber, to avoid affecting the free oscillation of the screen.

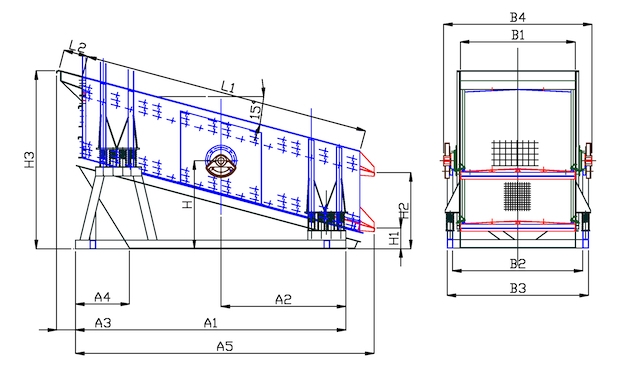

Screens with 2 decks

| Type | Α1 | Α2 | Α3 | Α4 | Α5 | Β1 | Β2 | Β3 | Β4 | Η | Η1 | Η2 | Η3 | L1 | L2 | Surface (sq.m.) |

Power (kw) |

Weight (kg) |

| VS1.5-4-2 | 3550 | 1780 | 270 | 330 | 3720 | 1500 | 1750 | 1870 | 1950 | 1150 | 220 | 870 | 2240 | 4000 | 300 | 6 | 10 | 2400 |

| VS1.7-5-2 | 4500 | 2260 | 270 | 310 | 4700 | 1700 | 1950 | 2080 | 2170 | 1280 | 180 | 850 | 2490 | 5000 | 300 | 8,5 | 15 | 3300 |

| VS1.7-6.2 | 5350 | 2640 | 290 | 350 | 5620 | 1700 | 1950 | 2080 | 2170 | 1540 | 240 | 1040 | 3000 | 6000 | 350 | 10,2 | 18 | 3500 |

| VS2-5-2 | 4500 | 2260 | 270 | 310 | 4700 | 2000 | 2250 | 2380 | 2480 | 1280 | 180 | 850 | 2490 | 5000 | 370 | 10 | 18 | 4500 |

| VS2-6-2 | 5350 | 2640 | 290 | 350 | 5620 | 2000 | 2250 | 2380 | 2480 | 1540 | 240 | 1040 | 3000 | 6000 | 350 | 12 | 22 | 5200 |

| VS2.4-6-2 | 5350 | 2640 | 290 | 350 | 5620 | 2400 | 2650 | 2780 | 2880 | 1540 | 240 | 1040 | 3000 | 6000 | 350 | 14,4 | 30 | 6000 |

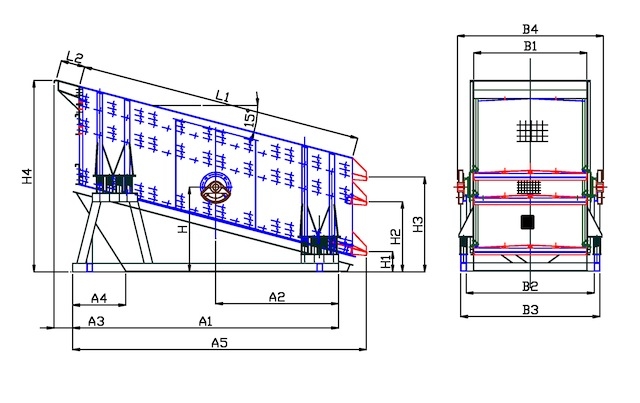

Screens with 3 decks

| Type | Α1 | Α2 | Α3 | Α4 | Α5 | Β1 | Β2 | Β3 | Β4 | Η | Η1 | Η2 | Η3 | Η4 | L1 | L2 | Surface (sq.m.) |

Power (kw) |

Weight (kg) |

| VS1.5-4-3 | 3550 | 1700 | 240 | 330 | 3750 | 1500 | 1750 | 1870 | 1950 | 1580 | 190 | 620 | 1300 | 2720 | 4000 | 300 | 6 | 18 | 2700 |

| VS1.7-5-3 | 4500 | 2110 | 240 | 330 | 4730 | 1700 | 1950 | 2080 | 2170 | 1870 | 280 | 670 | 1470 | 3110 | 5000 | 300 | 8,5 | 18 | 3700 |

| VS1.7-6.3 | 5500 | 2810 | 500 | 350 | 5750 | 1700 | 1950 | 2080 | 2170 | 1600 | 240 | 1130 | 1600 | 3500 | 6000 | 350 | 10,2 | 22 | 4000 |

| VS2-5-3 | 4680 | 2340 | 460 | 330 | 4890 | 2000 | 2250 | 2380 | 2480 | 1350 | 200 | 1000 | 1470 | 3140 | 5000 | 370 | 10 | 22 | 5100 |

| VS2-6-3 | 5500 | 2810 | 500 | 350 | 5750 | 2000 | 2250 | 2380 | 2480 | 1600 | 240 | 1130 | 1600 | 3500 | 6000 | 350 | 12 | 22 | 6000 |

| VS2.4-6-3 | 5900 | 2810 | 500 | 350 | 5750 | 2400 | 2650 | 2780 | 2880 | 1600 | 240 | 1130 | 1600 | 3500 | 6000 | 350 | 14,4 | 30 | 6500 |